Our Fox & Hounds Restaurant project included several sculpted trees. A sign hangs from a branch in one of these trees.

As a first step in creating the sign, my father opened the driftwood bitmap from our Texture Magic: Classic Collection in Photoshop.

Then he used the warp tool to shape the bitmap into a gentle 'S' curve.

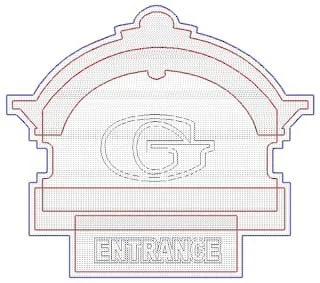

Once he was happy with the texture, he traced an outline with vectors and then imported them (and the modified bitmap) into EnRoute.

He also opened, copied and pasted the fox medallion he had previously completed. He resized it and added some shoulder pieces to make the sign flow. He added a sandblasted woodgrain texture to the shoulders.

My dad also created a separate relief for the lettering border and added some domed lettering.

Finally, he created a second copy of the sign and flipped it before adding the lettering to each side. (This way the two sides fit together to form a double sided sign.)

As you can see, the sign routed up quite nicely.

See you next week!